ZnO Additives For Rubber: What You Should Know

ZnO is the chemical formula for the compound Zinc Oxide. Zinc Oxide is considered a highly versatile compound that has found its way into various industries. The unusual and unique chemical properties are largely responsible for the versatility Zinc Oxide possesses.Metallurgical and chemical methods are the two divisions that are there in preparation of zinc oxide. Zinc Oxide is known to exhibit chemical stability high photostability, high electrochemical coupling co-efficiency and broad range of radiation absorption. Zinc Oxide is also classified as a semi-conductor.

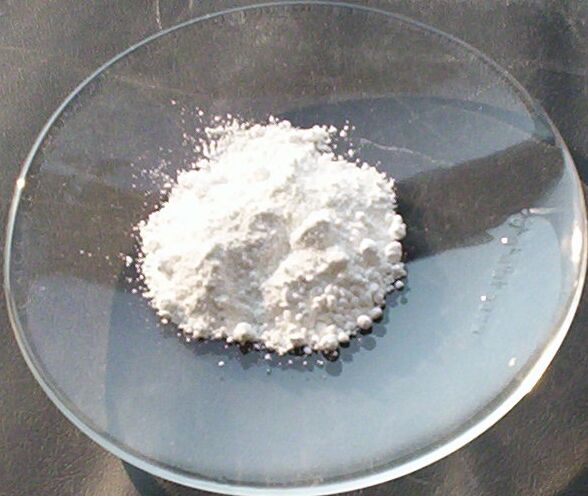

Zinc Oxide is known to exhibit a hexagonal structure. They also occur in a white powdery state and they turn yellow on application of heat. Zinc Oxide is known to not have any liquid state. They evaporate at 1300° C and sublimates at 1800° C. Therefore, these compounds are only found in gaseous or in solid state.

Zinc Oxide is a compound that is famed for its unique properties and great versatility. They are therefore employed by various industries for a wide array of jobs. The rubber industry in particular has been a primary consumer of Zinc Oxide. The ZnO Additives for Rubber industries in particular, have proven to be important.

Zinc Oxide is a compound that has optical, physical and chemical properties which are known to aid rubber production. Zinc Oxide is known to accelerate the curing of rubber along with other accelerators. Modern tyres are often loaded with Zinc Oxide. The semi-conducting nature of the compounds is responsible for their presence. They help absorb the heat that gets built up during the working of a tyre.

Usage and Advantages of ZnO as Additives for Rubber

Zinc Oxide is known to have various utilities. Curing acceleration and heat absorption are arguably its most important feature. The shelf life of zinc oxide is another important feature thathas prompted the rise in demand of Zinc Oxide.

The applications of this revolutionary compound are not just restricted to the rubber industry.Plastic production requires the same compound to acquire several important attributes. The acryliccompounds are imparted strength and resistance to heat on addition of zinc oxide.

Epoxide resin hasits treatment done by zinc oxide. When aliphatic polyamines are added to the mix, a higher tensilestrength and water resistance is acquired. Zinc oxide can make nylon fibres and mouldings highly fireresistant. These compounds also possess the ability to help produce nylon polymers and increasetheir resistance.